Precision Etching Beryllium Copper

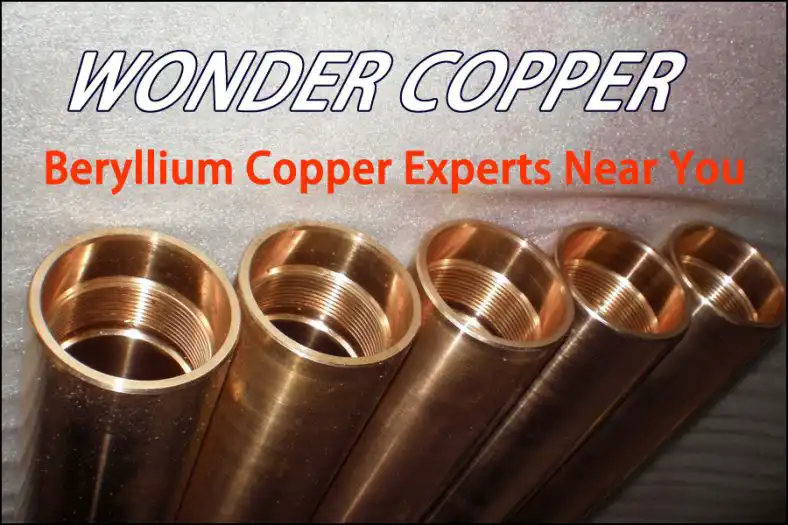

Wonder Copper(BE-CU.COM) has a reputation for precision etching quality parts from Beryllium Copper.Capable of handling parts sizes from 0.02 in. dia. to 24 x 60 in. and 0.001 to 0.08 in. thickness.

Introducing Wonder's "beryllium copper parts and products". Wonder copper will continue to develop and machining beryllium copper that support the foundation of society and help solve environmental issues.

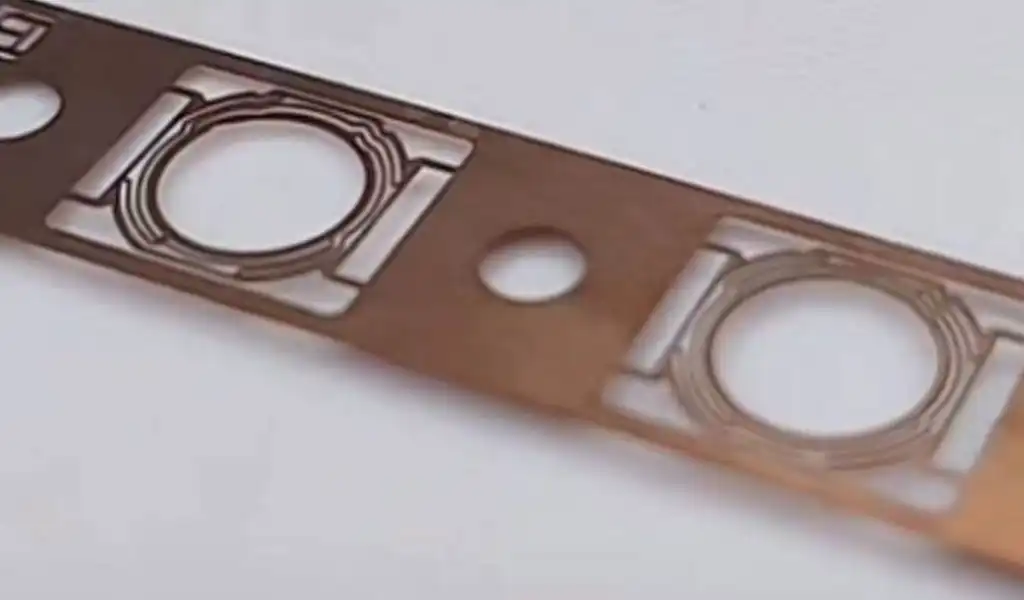

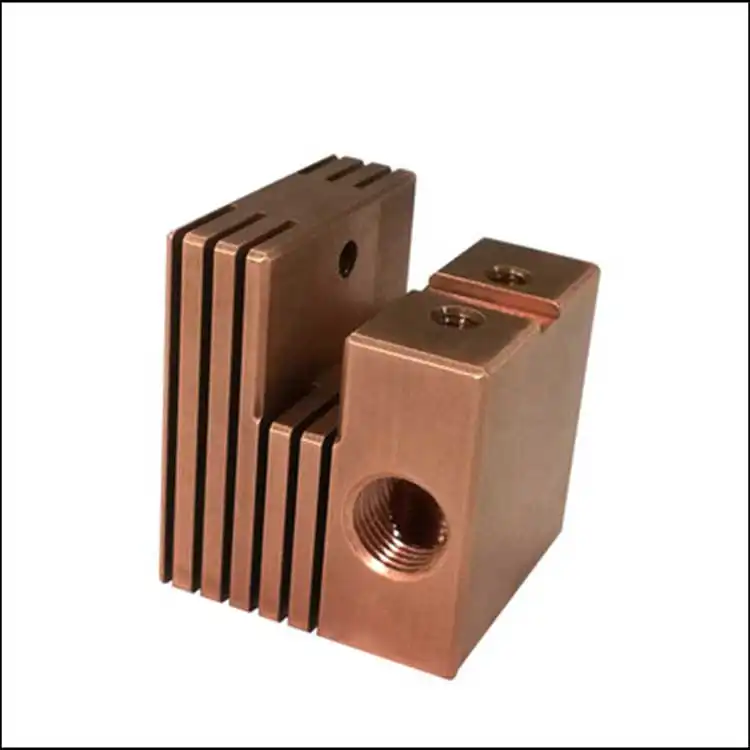

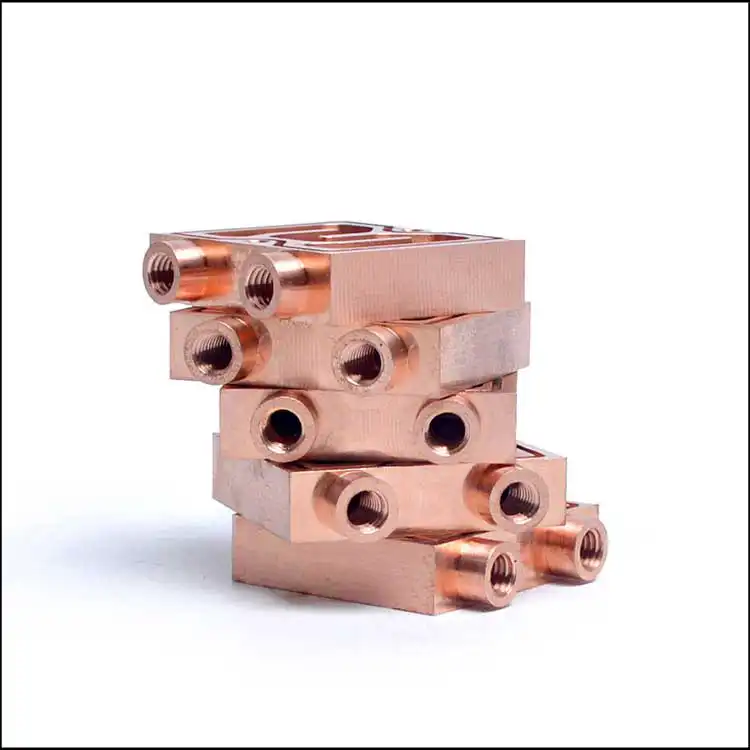

Beryllium copper Etching products

Beryllium copper is commonly used in electronic components due to its excellent electrical conductivity and spring properties. Etching can be used to create intricate patterns or fine-tune the shapes of electrical contacts, connectors, and other components.In the microelectronics industry, beryllium copper is often used in microelectromechanical systems (MEMS) and integrated circuits. Etching allows for precise shaping of beryllium copper structures at the micron level, enabling the fabrication of miniaturized components and devices.Etching can be used to fabricate lightweight yet durable components such as heat sinks, springs, and connectors for aerospace systems.Beryllium Copper Etching enables the production of intricate components for devices such as surgical instruments, pacemakers, and implantable sensors.

Beryllium copper's combination of electrical conductivity and mechanical strength makes it suitable for telecommunications applications. Etching can be utilized to fabricate high-performance components like connectors, antennas, and transmission lines for telecommunications infrastructure.Beryllium copper is used in precision instruments where dimensional stability and reliability are critical. Etching allows for the fabrication of precise components such as springs, contacts, and sensor elements in devices like measuring instruments and scientific equipment.

Beryllium Copper Etching Services

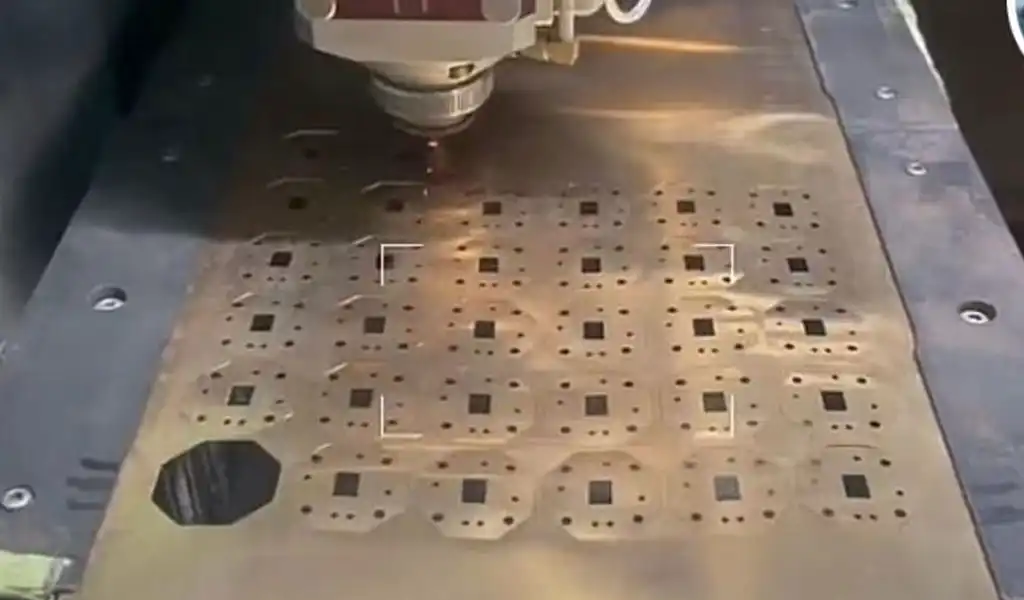

The conventional method for etching beryllium copper plates typically involves either stamping or laser processing. However, stamping processes struggle with burrs and oil contamination issues, and maintaining processing precision can be challenging. BE-CU employs chemical etching, resulting in high precision, burr-free products, with flexible design alteration capabilities.

To effectively manufacture such precision products, the primary requirement is the availability of a purified production workshop. The size, width, presence of breakpoints, and recesses in the mesh of etched beryllium copper plates will undoubtedly affect product correctness and filtration sensitivity in the future. Our purification workshop operates at a level of cleanliness reaching ten thousand, a prerequisite for processing such products! Additionally, we possess multiple imported beryllium copper etching production lines to ensure the accuracy of etching processing, along with a comprehensive quality control system to prevent defective products from reaching customers.

Collaborating with several Fortune 500 companies, BE-CU provides a compelling reason to choose us! The materials used by the company are primarily imported, enabling etching processing of various materials and making us the preferred domestic alternative to Taiwanese and Japanese production. Depending on material thickness, the minimum aperture can reach 0.05mm, flatness can be maintained below 0.02mm, and the minimum tolerance can achieve +/-0.0075mm.

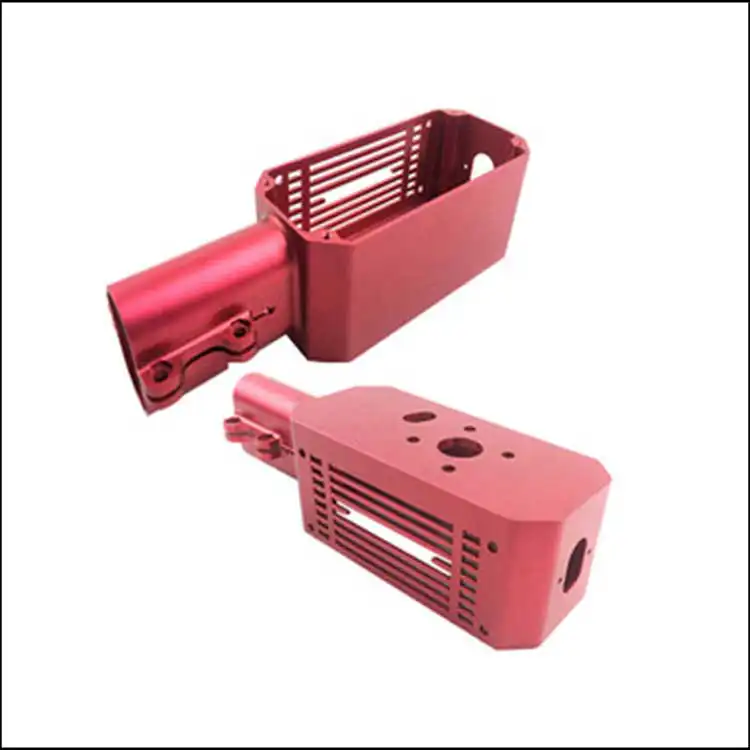

Beryllium Copper Parts Case Studies

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

|---|---|---|---|---|---|---|---|

| C17200 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17300 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | 0.2-0.6 | 0.15 | 0.15 |

| C17500 | 0.4-0.7 | Co 2.4-2.7 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17510 | 0.2-0.6 | Co≤0.3,Ni 1.4-2.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| QBe2.0 | 1.8-2.1 | Ni 0.2-0.5 | Margin | 0.15 | 0.005 | 0.15 | 0.15 |

| BeCo1Ni1 | 0.4-0.7 | Co 0.8-1.3,Ni 0.8-1.3 | Margin | 0.02 | - | 0.02 | 0.04 |

Mechanical properties and conductivity analysis

(AT/TF00)

| Numbering | Tensile Strength/MPa | Yield Strength/MPa | Elongation% | Hardness | Conductivity%IACS |

|---|---|---|---|---|---|

| C17200 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17300 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17500 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| C17510 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| QBe2.0 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 18-20 |

| BeCo1Ni1 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

Available Status

| Brush Name | ASTM Name | Description |

|---|---|---|

| A | TB00 | Solution annealing state (quenched state) |

| ½H | TD01 | Quarter hard |

| ½H | TD02 | Half hard (semi-hard) |

| ¾H | TD03 | Three-quarters hard |

| H | TD04 | Hard state (full hard) |

| AT | TF00 | Standard aging heat treatment in quenched state |

| ¼HT | TH01 | Quarter hard standard aging heat treatment |

| ½HT | TH02 | Half-hard standard aging heat treatment |

| ¾HT | TH03 | Three-quarters hard standard aging heat treatment |

| HT | TH04 | Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging) |

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).