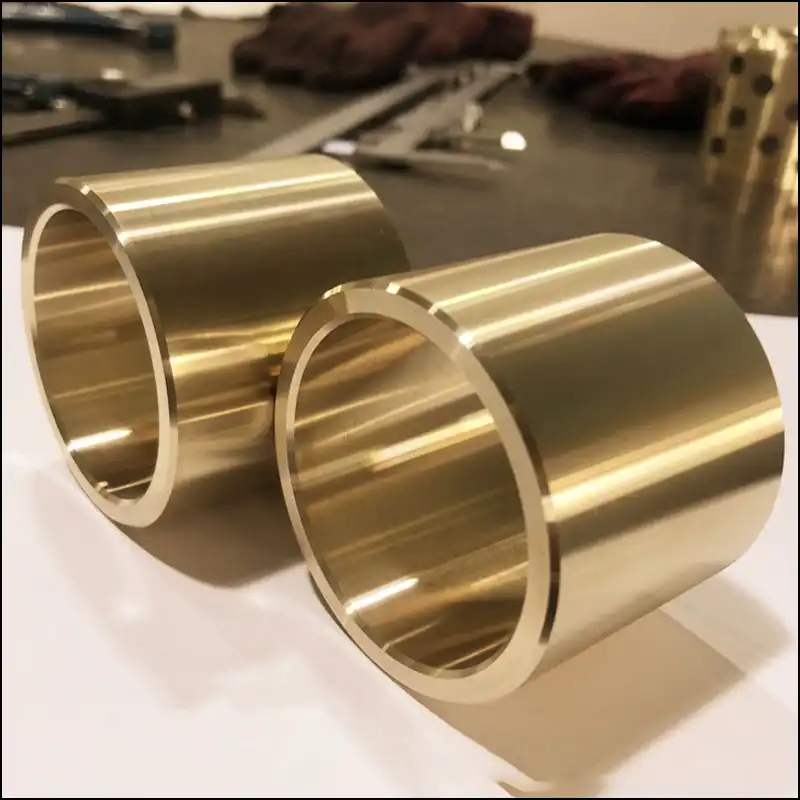

Beryllium Copper Rings/sleeve

Wonder copper are capable of producing beryllium copper rings according to Customer’s drawing and available samples or detailed inquiry.

Although custom machining & custom beryllium copper rings is highly challenging, customers cannot afford unacceptable delivery delays. Mastering technical challenges while maintaining an uninterrupted reliable supply is an important core competency at Wonder copper. The Wonder copper team of manufacturing professionals knows the distinctive properties of all the beryllium copper alloys in the Stainless category, and adjust the production process to maximize production efficiency.

Beryllium Copper Rings Available products

Typical application of Beryllium Copper Rings

Wonder copper advantage:

Wonder Copper Rings Case Studies

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

|---|---|---|---|---|---|---|---|

| C17200 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17300 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | 0.2-0.6 | 0.15 | 0.15 |

| C17500 | 0.4-0.7 | Co 2.4-2.7 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17510 | 0.2-0.6 | Co≤0.3,Ni 1.4-2.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| QBe2.0 | 1.8-2.1 | Ni 0.2-0.5 | Margin | 0.15 | 0.005 | 0.15 | 0.15 |

| BeCo1Ni1 | 0.4-0.7 | Co 0.8-1.3,Ni 0.8-1.3 | Margin | 0.02 | - | 0.02 | 0.04 |

Mechanical properties and conductivity analysis

(AT/TF00)

| Numbering | Tensile Strength/MPa | Yield Strength/MPa | Elongation% | Hardness | Conductivity%IACS |

|---|---|---|---|---|---|

| C17200 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17300 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17500 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| C17510 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| QBe2.0 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 18-20 |

| BeCo1Ni1 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

Available Status

| Brush Name | ASTM Name | Description |

|---|---|---|

| A | TB00 | Solution annealing state (quenched state) |

| ½H | TD01 | Quarter hard |

| ½H | TD02 | Half hard (semi-hard) |

| ¾H | TD03 | Three-quarters hard |

| H | TD04 | Hard state (full hard) |

| AT | TF00 | Standard aging heat treatment in quenched state |

| ¼HT | TH01 | Quarter hard standard aging heat treatment |

| ½HT | TH02 | Half-hard standard aging heat treatment |

| ¾HT | TH03 | Three-quarters hard standard aging heat treatment |

| HT | TH04 | Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging) |

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).