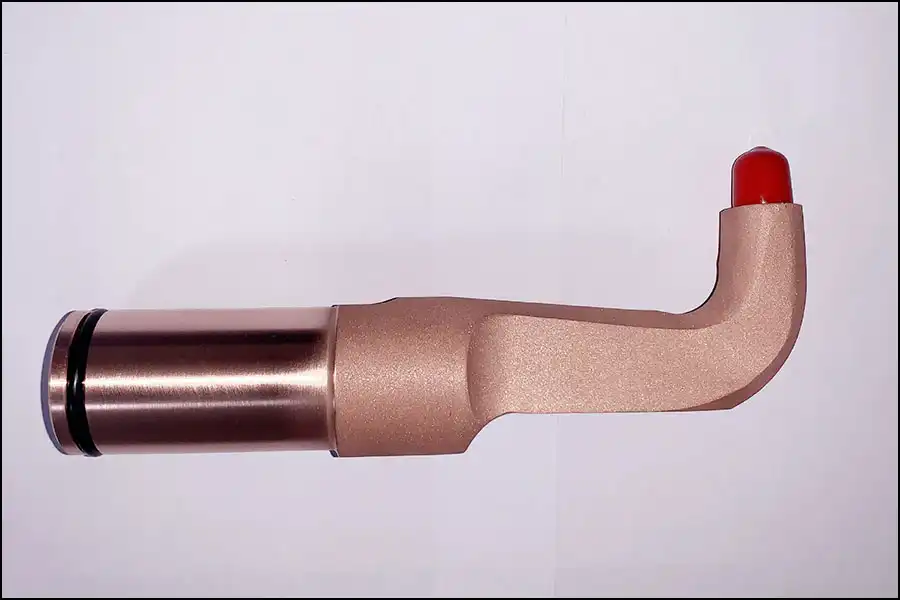

Beryllium Copper Welding Electrodes/Wheels/Parts

Wonder copper are capable of producing beryllium copper welding electrodes/wheels/parts according to Customer’s drawing and available samples or detailed inquiry.

Wonder copper is capable of producing the beryllium copper welding electrode, welding tips, welding discs, contact tips, shafts, beryllium copper seam welding wheels, spot welding tips, spot welding electrode, electrode caps, adaptors, holders, etc…

In arc welding an electrode is used to conduct current through a workpiece to fuse two pieces together. Depending upon the process, the electrode is either consumable, in the case of gas metal arc welding or shielded metal arc welding, or non-consumable, such as in gas tungsten arc welding. For a direct current system the weld rod or stick may be a cathode for a filling type weld or an anode for other welding processes. For an alternating current arc welder the welding electrode would not be considered an anode or cathode.

Welding Electrodes/Wheels/Parts Available products

Welding Electrodes/Wheels/Parts Typical application

Electrodes/Wheels/Parts Case Studies

Chemical Composition

Executive standard:ASTM/GB/T5233-2001/EN12163(%max., unless shown as range or min.)

| Numbering | Be | Co+Ni | Cu | Fe | Pb | Si | Al |

|---|---|---|---|---|---|---|---|

| C17200 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17300 | 1.8-2.0 | Co+Ni≥0.2 | Margin | 0.15 | 0.2-0.6 | 0.15 | 0.15 |

| C17500 | 0.4-0.7 | Co 2.4-2.7 | Margin | 0.15 | - | 0.15 | 0.15 |

| C17510 | 0.2-0.6 | Co≤0.3,Ni 1.4-2.2 | Margin | 0.15 | - | 0.15 | 0.15 |

| QBe2.0 | 1.8-2.1 | Ni 0.2-0.5 | Margin | 0.15 | 0.005 | 0.15 | 0.15 |

| BeCo1Ni1 | 0.4-0.7 | Co 0.8-1.3,Ni 0.8-1.3 | Margin | 0.02 | - | 0.02 | 0.04 |

Mechanical properties and conductivity analysis

(AT/TF00)

| Numbering | Tensile Strength/MPa | Yield Strength/MPa | Elongation% | Hardness | Conductivity%IACS |

|---|---|---|---|---|---|

| C17200 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17300 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 22-28 |

| C17500 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| C17510 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

| QBe2.0 | 1160-1380 | 980-1240 | 3-15 | 36-42HRC | 18-20 |

| BeCo1Ni1 | 700-920 | 560-710 | 10-25 | 92-100HRB | 45-60 |

Available Status

| Brush Name | ASTM Name | Description |

|---|---|---|

| A | TB00 | Solution annealing state (quenched state) |

| ½H | TD01 | Quarter hard |

| ½H | TD02 | Half hard (semi-hard) |

| ¾H | TD03 | Three-quarters hard |

| H | TD04 | Hard state (full hard) |

| AT | TF00 | Standard aging heat treatment in quenched state |

| ¼HT | TH01 | Quarter hard standard aging heat treatment |

| ½HT | TH02 | Half-hard standard aging heat treatment |

| ¾HT | TH03 | Three-quarters hard standard aging heat treatment |

| HT | TH04 | Hard standard aging heat treatment (a process of comprehensive strengthening of deformation and aging) |

Note: In the Brush name:

- "A" represents the state of solution annealing (annealed, the alloy is in the softest state, easy to be stamped and formed, and needs to be cold worked or strengthened during the direct failure period);

- "H" stands for cold processing state (hard);

- "T" means that the material has been aging hardened by standard heat treatment (heat treatment means the state of aging strengthening heat treatment).