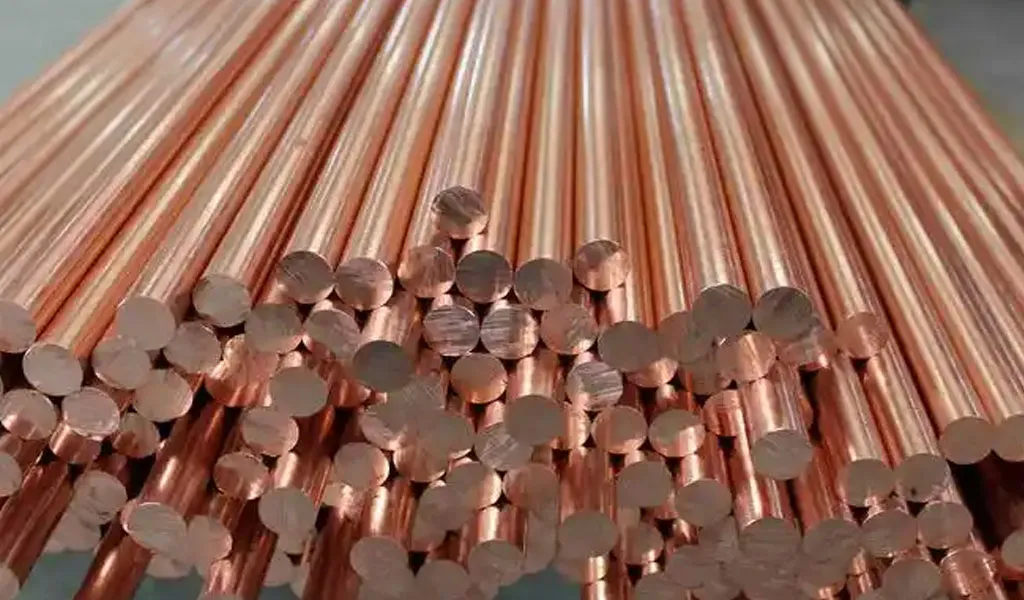

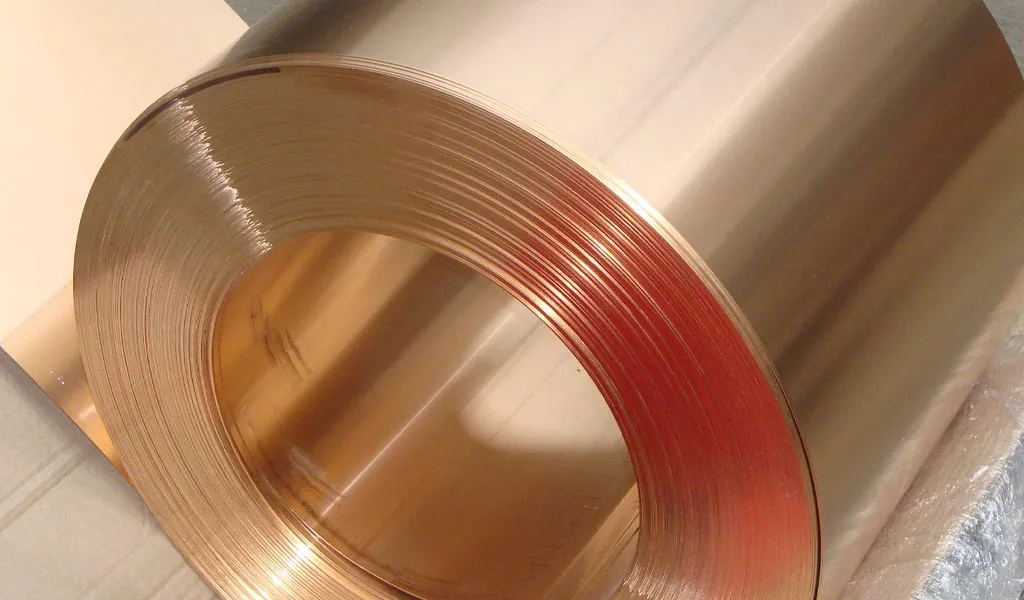

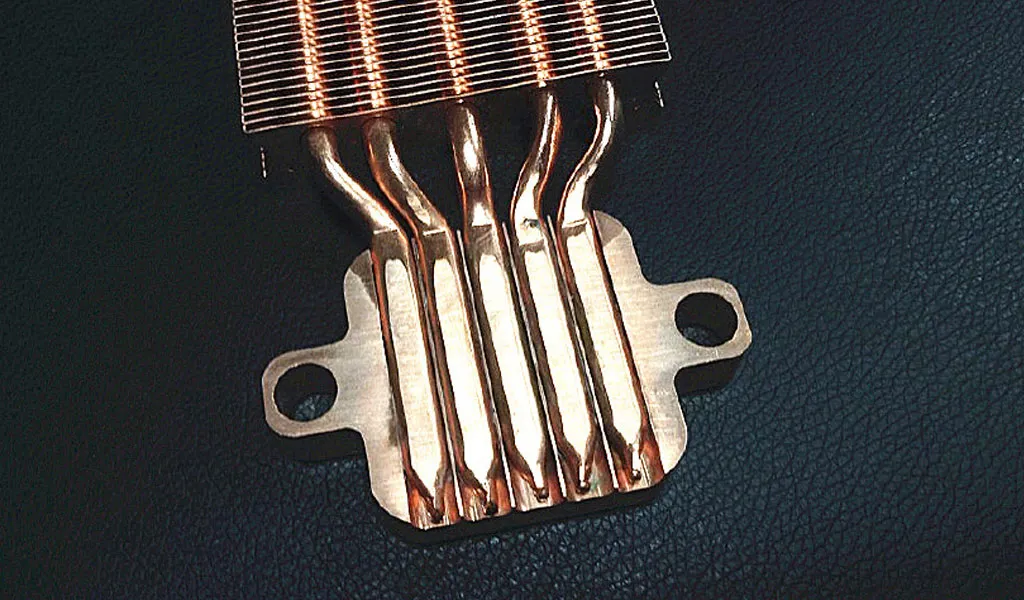

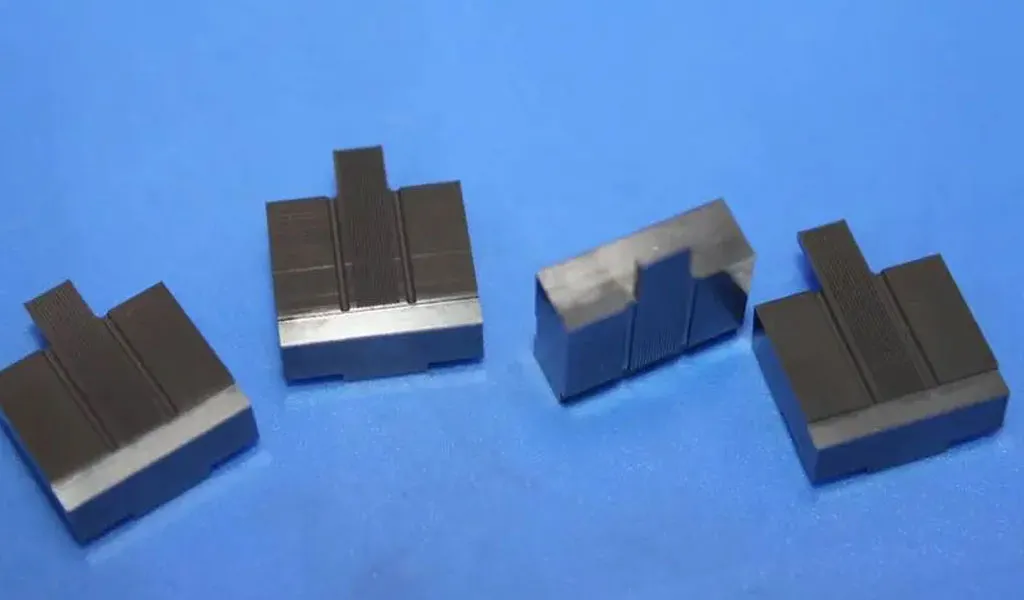

The Application Difference Between Brass And Copper

In order to save costs, many manufacturers use brass instead of copper, which confuses the distinction between brass and copper, which may cause a lot of waste. So what is the difference between brass and copper in application? Red copper and brass composition and basic parameter analysis Brass: An alloy…

Read More