Heat treatment process and technical requirements for beryllium bronze elastic components

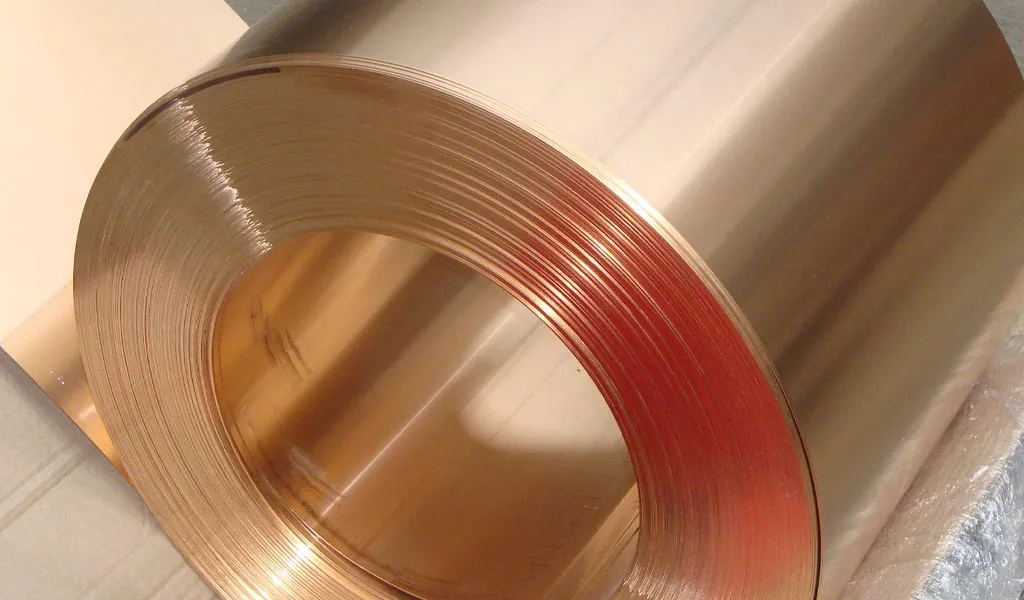

Beryllium bronze is primarily made from a metal called beryllium, combined with some processed materials. It possesses excellent elasticity and can be used as a tool for buffering the connections between two or more mechanical components. Therefore, products made from beryllium bronze can effectively protect mechanical components from wear. Additionally,…

Read More