Beryllium Copper Processing Process

STEP1.Slitting Basic Process

WONDER COPPER has 6 precision slitting production lines, all of which are high-end equipment imported from Taiwan, and the blades are imported from Germany. The slitting machine discharges the outer diameter of 1000mm, the inner diameter of 200-500mm, and the load-bearing capacity can reach 2000-3000KG. The slitting width is 4-600mm, and the slitting accuracy can reach +0, -0.1mm. The thickness of vermicelli material is 0.05-1mm. Capable of slitting beryllium copper precision strips.

At present, Wonder Copper has one shift. Because of the wide range of slitting specifications, the current daily average production capacity is about 30 tons. The theoretical maximum production capacity, 0.4x400mm material, one machine can continuously slitting, about 22 tons can be divided in 8 hours, and 5 machines can be divided into 110 tons per shift. 0.1x400mm, one machine can uninterrupted slitting, 8 hours can be divided into about 8 tons, 5 machines can be divided into 40 tons per shift.

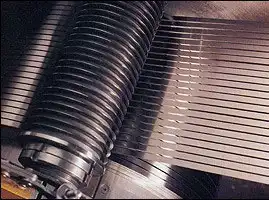

STEP2.Rolling Milling Process

At present, our rolling plant has two reversible cold rolling mills, two annealing furnaces, two grinders and other equipment. The thickness range processed by the reversible cold rolling mill is between 0.1mm-1.2mm, the hardness range is between 1/4H-H, the thickness tolerance is between 0.01mm-0.05mm, and the width of the steel strip is between 150mm-350mm. The capacity is about 400KG/H per unit.

The thickness range that the annealing furnace can produce is between 0.10mm—1.0mm, the annealing speed is between 1.0—12 meters, the hardness of the annealed material is 304HV160—190 degrees, 301HV190—210 degrees, the width of the annealed steel strip Between 80-400MM, the production capacity is about 200KG/H per unit.

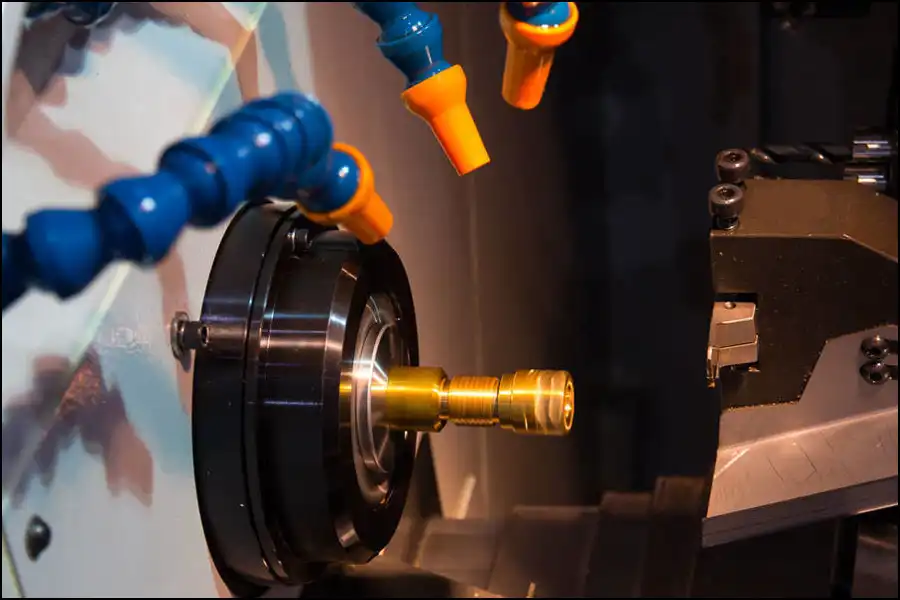

STEP3.Beryllium Copper Electroplating

Electroplating is the process of using the principle of electrolysis to plate a thin layer of other metals or alloys on the surface of certain metals. It is the process of using electrolysis to attach a layer of metal film to the surface of the metal or other material to prevent corrosion and improve Abrasion resistance, conductivity, reflectivity, and enhance aesthetics.

During electroplating, the plated metal or other insoluble materials are used as the anode, the workpiece to be plated is used as the cathode, and the cations of the plated metal are reduced on the surface of the workpiece to be plated to form a coating. In order to eliminate the interference of other cations and make the coating uniform and firm, it is necessary to use a solution containing the coating metal cations as the electroplating solution to keep the concentration of the coating metal cations unchanged. The purpose of electroplating is to plate a metal coating on the substrate to change the surface properties or size of the substrate. Electroplating can enhance the corrosion resistance of metals (corrosion-resistant metals are mostly used for coating metals), increase hardness, prevent abrasion, improve conductivity, lubricity, heat resistance and surface aesthetics.

A technology that uses electrolysis to deposit a metal coating with good adhesion but different properties from the base material on mechanical products. The electroplating layer is more uniform than the hot dip layer, generally thinner, ranging from a few microns to tens of microns. Through electroplating, it is possible to obtain decorative protective and various functional surface layers on mechanical products, and to repair worn and processed workpieces.

STEP4.Beryllium Copper Spray Painted

- Capacity: 6-8 tons per day;

- Process Capability:xxxx

- Printable material thickness: 0.05mm-0.5mm

- Printable material width: within 220mm;

- Printing materials involved: white copper, stainless steel, aluminum, copper, tinplate;

- Printing colors involve: yellow, black, white;

- Single-sided and double-sided printing can be performed.

STEP5.Beryllium Copper Inspection